Toyota Cuts Production Forecast (Again) Citing Covid Outbreaks In Southeast Asia And Supply Shortages

Yet another day, another auto company cutting its production forecast due to parts shortages. Stop us if you've heard this one before...

Toyota is the latest legacy auto manufacturer to come out and announce it is revising its full year production forecast by about 300,000 units to 9 million units for the year, Bloomberg reported Friday morning.

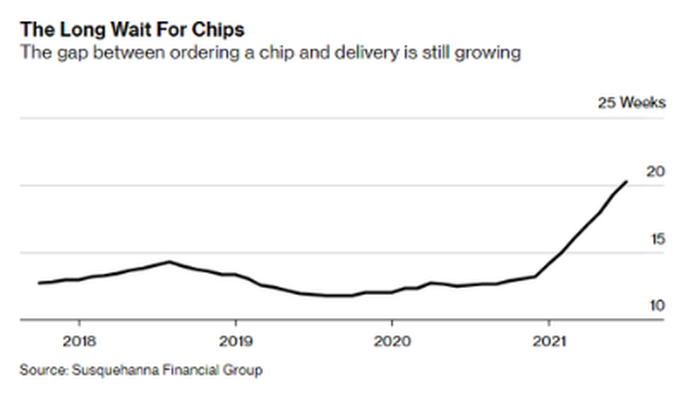

The company is citing the Covid outbreaks in Southeast Asia that we have written about extensively, as well as continued shortages resulting from the semiconductor drought.

Output will be lower by 70,000 units in September and 330,000 units in October, the automaker said. It says its outlook for November, only two months away, is still "unclear" despite "very strong" demand.

We had cited Malaysian Covid outbreaks as throwing a wrench into the gears of already-stressed auto manufacturing plans for the summer. IHS predicts that 2.1 million units could wind up being lost in the third quarter of 2021 alone.

Malaysia is home to names like Infineon Technologies AG, NXP Semiconductors NV and STMicroelectronics NV, who all have operating plants in the country. With Covid infections soaring locally, plans for lifting lockdowns and re-opening production looked as though they could fall by the wayside last month. Daily infections were up to 20,000 per day in August, up from just 5,000 per day in late June.

There is still little in the way of normalization to be optimistic about until the second quarter of 2022, IHS estimated last month. An IHS report stated: “The situation is still fraught with challenges. We are also seeing additional volatility due to Covid-19 lockdown measures in Malaysia where many back-end chip packaging and testing operations are performed.”

Wong Siew Hai, president of the Malaysia Semiconductor Industry Association, commented: “Malaysia is a key player in the global semiconductor trade. Thus, any disruption anywhere along the supply chain will have knock-on effects elsewhere in the ecosystem.”

Also last month, Ford cited “a semiconductor-related part shortage as a result of the Covid-19 pandemic in Malaysia" as a reason for temporarily suspending production at one U.S. plant.

Recall in late August we noted that VW and Toyota had already cut guidance. VW' said at the time its main plant in Wolfsburg was only going to be running on its early shift after summer break due to the lack of supply. Its plant in Wolfsburg is the "world's biggest car plant" and employs about 60,000 people. Audi is also pausing production temporarily, extending its summer break by one week, the report noted.

Toyota also said it was planning to temporarily stop 14 plants in September while lowering its production by 40%.

Global shortages of semiconductors could wind up cutting worldwide production of autos this year by about 7.1 million vehicles, Bloomberg predicted last month. Tyler Durden Fri, 09/10/2021 - 11:35

http://dlvr.it/S7KFl0

No comments:

Post a Comment